HINZ Steuerungstechnik GmbH

Success with NimBit IoTBreeze

Quality improvement through precise system control

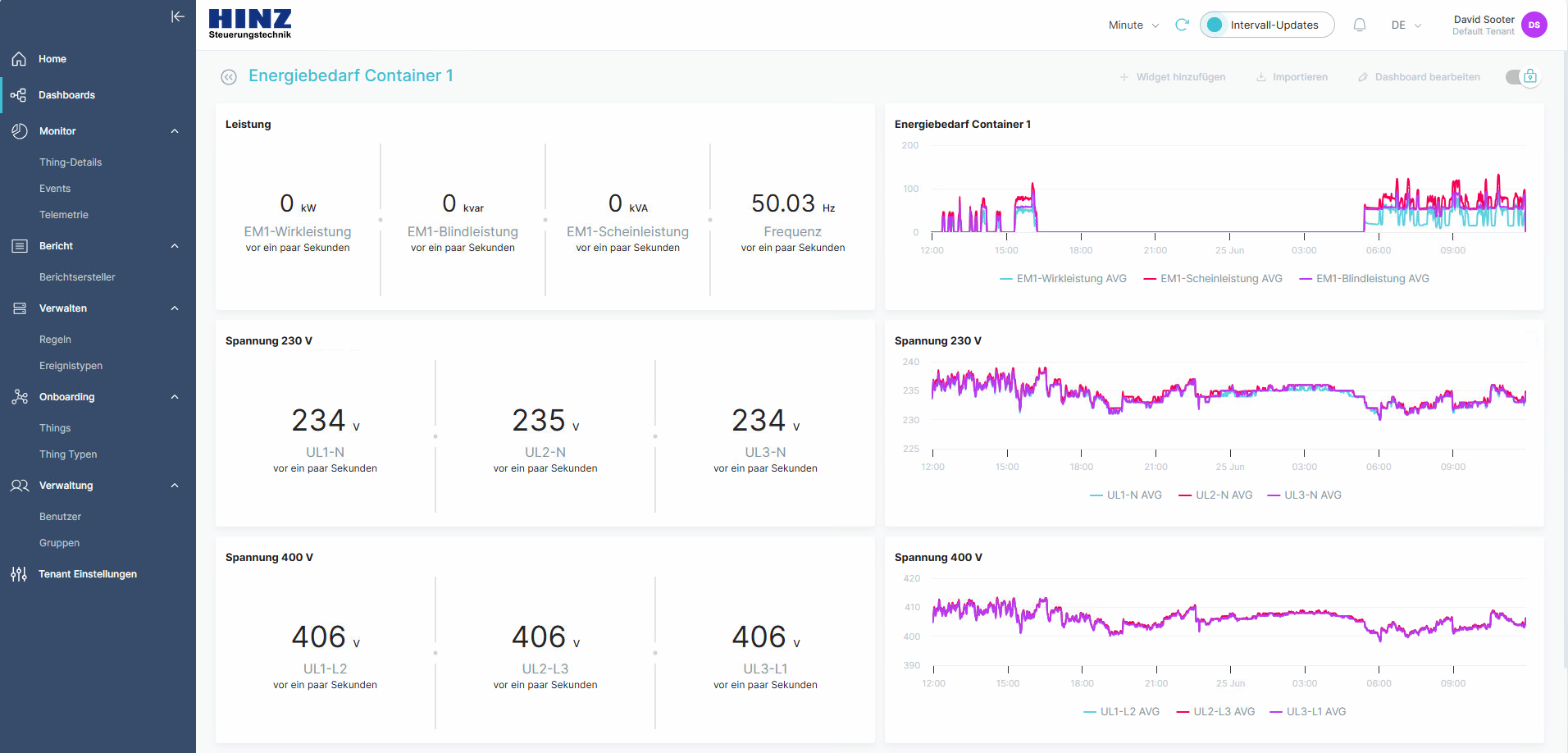

HINZ Steuerungstechnik GmbH pursues a clear vision: to enhance quality and throughput by offering precise system control tailored to specific situations. By utilizing NimBit IoTBreeze, their flagship product MEBAS was optimized through the real-time visualization of sensor data and the calculation and display of key metrics. This resulted in increased output and improved quality of the end products produced in a gravel plant.

The company and its challenges

HINZ Steuerungstechnik GmbH is a leading provider of switchgear, electronic installation, remote maintenance management, and software solutions for the mineral building materials industry. Their solutions enable complex plants to precisely control and monitor essential processes such as weighing, dosing, and loading. By coordinating control processes across several sub-plants, HINZ Steuerungstechnik GmbH helps sand and gravel plants enhance the quality of their products, including sand, gravel, and mixtures. Additionally, by adapting to external influences such as temperature, rainfall, and wind, the energy efficiency and sustainability of these plants can be significantly improved.

The solution

By utilizing the managed IoT solution NimBit IoTBreeze, HINZ Steuerungstechnik GmbH was able to quickly identify even the smallest deviations and optimization needs within the plant control system, allowing for immediate corrective actions. These adaptations in the plant processes led to further improvements in the end product. The close cooperation between the experts at HINZ Steuerungstechnik GmbH and the team at NimBit GmbH ensured that customer-specific requirements were implemented swiftly and efficiently, including the integration of a spare parts shop.

An extended solution using edge computing

Due to the remote location of the mines, the vast amounts of data generated by the machines, and the requirement to keep this data offline, HINZ implemented a 100% edge computing scenario. NimBit IoTBreeze is deployed locally at the edge, enabling faster data processing and supporting real-time driven processes. Using the rules engine and data pipelines, HINZ can enrich the data, perform calculations, and trigger events without the data ever leaving the deployment site.

By utilizing Azure IoT Hub Edge, updates can be seamlessly sent to remote edge systems without downtime or significant effort, making the deployment of new features a breeze. Deploying at the edge also offers additional benefits, such as direct communication with connected devices without the need for extra hardware, intermediate software, or brokers. This approach allows for easy extension of functionality and the seamless addition of new values and features.

Features and benefits

- Real-time dashboards:

Visualization in real time enables an immediate response to deviations and optimization requirements. - Direct access to PLCs:

Direct communication with the control systems without additional hardware or software. - Processing of around 500,000 messages per day:

Effective data management despite high data volumes. - Automated notifications:

Immediate notification of critical events for fast troubleshooting. - Integration of sensors and measurement technology:

Integrated data acquisition and monitoring. - Energy data management:

Optimizing energy efficiency through precise monitoring and control. - Reporting, documentation and visualization:

Comprehensive reporting and visualization for transparent processes. - Machine fine-tuning:

Optimizing the output of the entire system through precise control and adjustment. - Dynamic expansion of logic and controllers:

Flexibility through the definition and adaptation of rules for continuous improvements.

When does edge make sense?

Edge scenarios offer various advantages compared to managed cloud environments. Particularly in situations where a significant amount of data is generated by IoT sensors, it often involves balancing the required level of granularity (especially for real-time dashboards) with the costs associated with increased data volume. For this use case at HINZ Steuerungstechnik GmbH, which produces almost 500,000 messages per day, an edge scenario is an excellent fit.

While an edge scenario may not be ideal for every situation and does require additional administrative effort, it proves highly beneficial in scenarios where data latency is critical or data needs to be kept separate. NimBit offers the IoTBreeze solution in various forms - from fully managed cloud scenarios to edge or hybrid solutions that combine the best of both worlds.

This is just the beginning. We continue to work closely with HINZ Steuerungstechnik GmbH and our partner companies to drive further innovations in sectors such as mining, gravel plants, and the recycling industry.

Interested?

Schedule a free initial consultation now and gain an insight into our solutions and services.