Improving quality through precise plant control

HINZ Steuerungstechnik GmbH pursues a clear vision: to increase quality and throughput through precise plant control tailored to specific situations. With NimBit IoTBreeze, the flagship product MEBAS was optimized by visualizing real-time sensor data and determining and displaying key performance indicators. This led to an increase in output and quality of the end products manufactured in a gravel plant.

The company and its challenges

HINZ Steuerungstechnik GmbH is a leading provider of switchgear, electrical installation, remote maintenance management, and software solutions for the mineral building materials industry.

With solutions from HINZ Steuerungstechnik GmbH, complex plants can precisely control and monitor their typical requirements in the areas of weighing, dosing, and loading. Through coordinated control processes across multiple subsystems, sand and gravel plants can improve the quality of their products, such as sand, gravel, or mixtures. In addition, the energy efficiency and sustainability of the plants can be increased by adapting to external influences such as temperature, precipitation, and wind.

Solution

With NimBit IoTBreeze managed IoT solution, it was possible to identify even the smallest deviations and optimization requirements in the plant control system within a very short time and to respond accordingly. The processes in the plant were adjusted based on the results, which led to further improvement of the end product. The close cooperation between the experts at HINZ Steuerungstechnik GmbH and the team at NimBit GmbH enabled fast and efficient implementation and realization of the customer-specific requirements, including the integration of a spare parts shop.

Extended solution with edge computing

Due to the remote location of the mines, the large amounts of data produced by the machines, and the desire to keep this data offline, HINZ implemented a complete edge scenario.

NimBit IoTBreeze is used entirely locally at the edge, i.e., locally, which enables faster data processing and supports real-time-driven processes. With the help of the Rules Engine and data pipelines, HINZ can enrich the data, perform calculations, and trigger events without the data having to leave the site.

By using Azure IoT Hub Edge, we can seamlessly send updates to the remote edge systems without downtime or effort, making it easy to apply new features. Deployment at the edge also offers additional advantages, as we can communicate directly with the connected devices without using additional hardware, intermediate software, or brokers. This allows us to easily extend functionality or seamlessly add new values and features.

Features and benefits

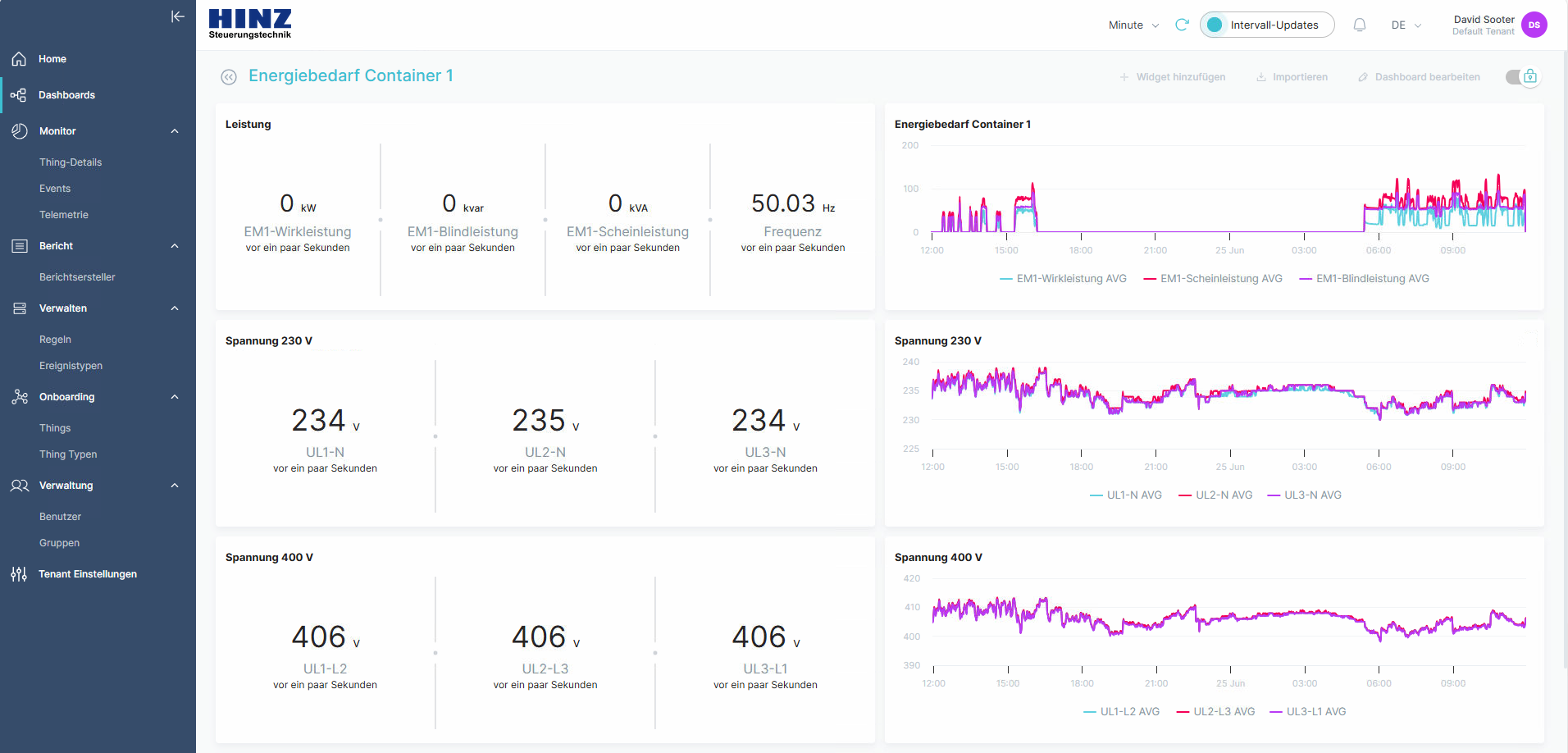

Real-time dashboards:

Real-time visualization enables immediate response to deviations and optimization requirements.

Direct access to PLC:

Direct communication with control systems without additional hardware or software.

Processing of nearly 500,000 messages per day:

Effective data management despite high data volumes.

Automated notifications:

Immediate notification of critical events for rapid problem solving.

Integration of sensors and measurement technology:

Comprehensive data acquisition and monitoring.

Energy data management:

Optimization of energy efficiency through precise monitoring and control.

Reporting, documentation, and visualization:

Comprehensive reporting and visualization for transparent processes.

Fine-tuning of machines:

Optimization of the output of the entire plant through precise control and adjustment.

Dynamic expansion of logic and controllers:

Flexibility through the definition and adaptation of rules for continuous improvement.

At the edge of the network

Edge scenarios offer various advantages over managed cloud environments. Especially in scenarios where large amounts of data are generated by IoT sensors, it is often a balancing act between the required level of detail (especially for real-time dashboards) and the costs associated with the increased data volume. For the use case at HINZ Steuerungstechnik GmbH, which produces almost 500,000 messages per day, an edge scenario makes sense.

And although an edge scenario is not ideal for every situation and requires additional administrative effort, it can be very useful in scenarios where latency is an issue or data needs to be kept separate. NimBit offers the IoTBreeze solution in all variants – from fully managed scenarios in the cloud to edge or hybrid solutions that combine the best of both worlds.

That's just the beginning: We continue to work closely with HINZ Steuerungstechnik GmbH and partner companies to create further innovations for mining, gravel pits, and the recycling industry, for example.

Interested?

Book an initial consultation now and gain insight into our solutions and services.