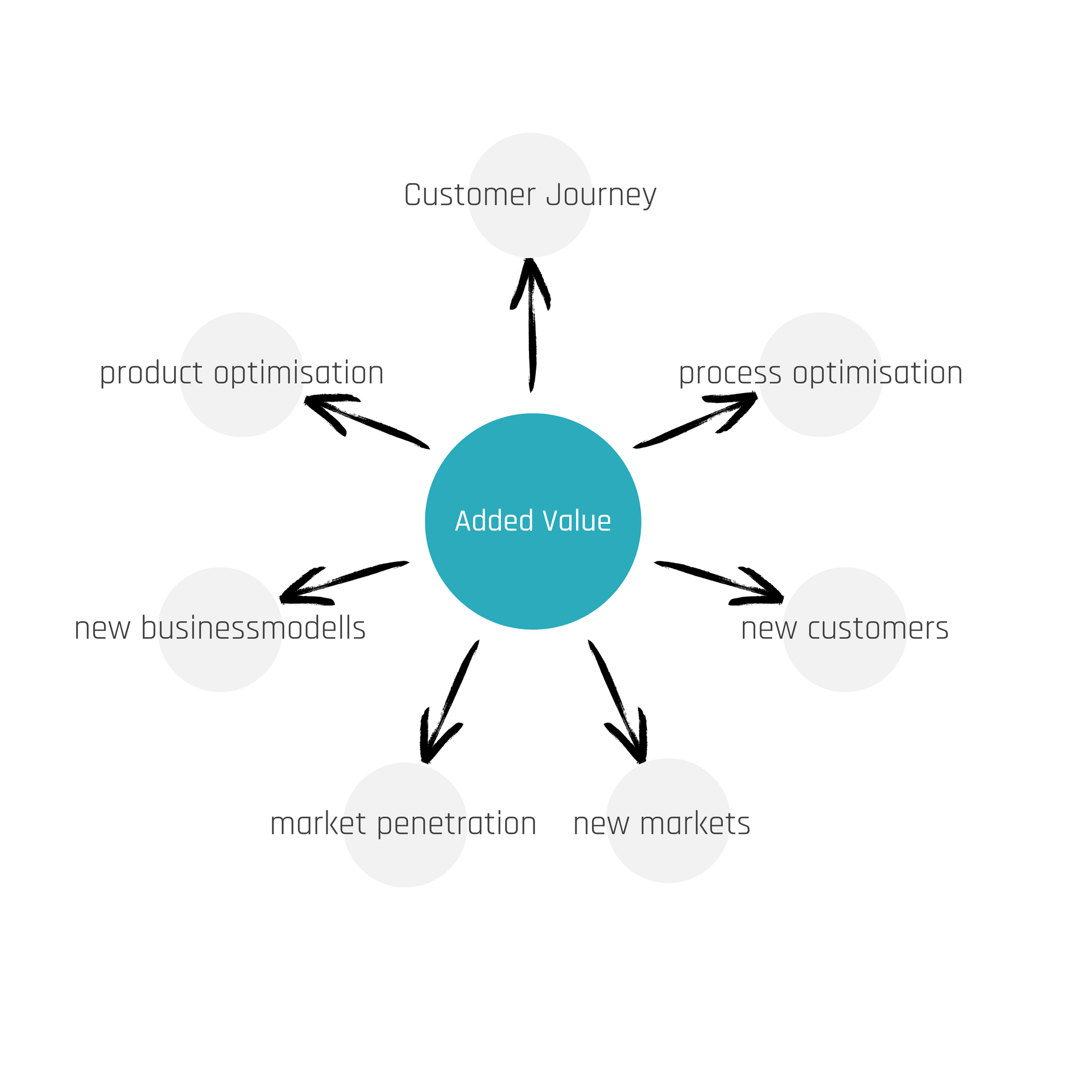

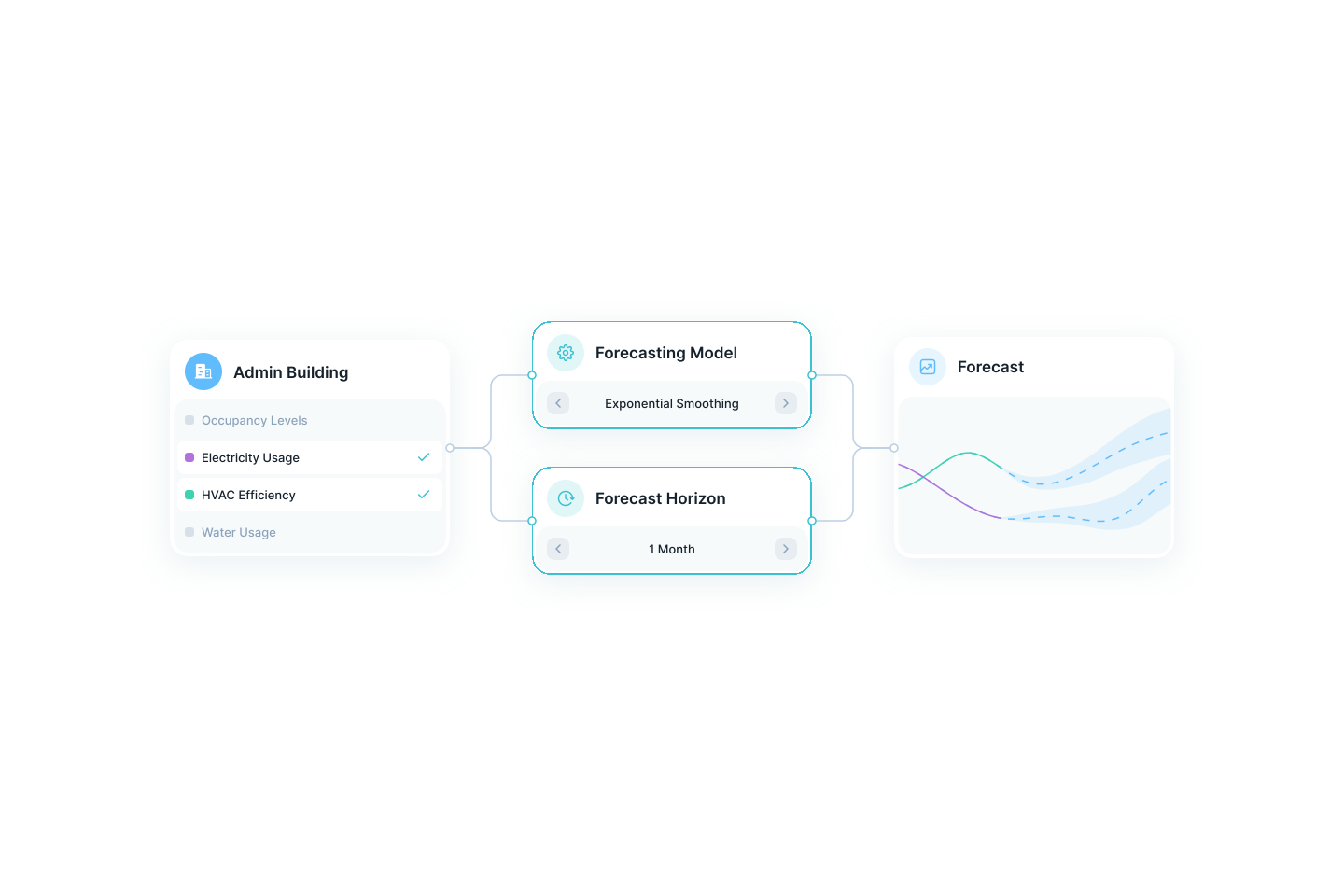

IoTBreeze - Generating Added Value from Data

Whether your machines, systems, or other devices – in short, assets – are already equipped with the necessary sensor technology (e.g., cameras, bus systems, IoT interfaces) or not, sooner or later the central question arises: How can you efficiently use your data to generate real added value?

Because there is no doubt: A large volume of data is not enough. Without structured analysis and intelligent linking, valuable insights remain unused, and real optimization potential stays hidden.

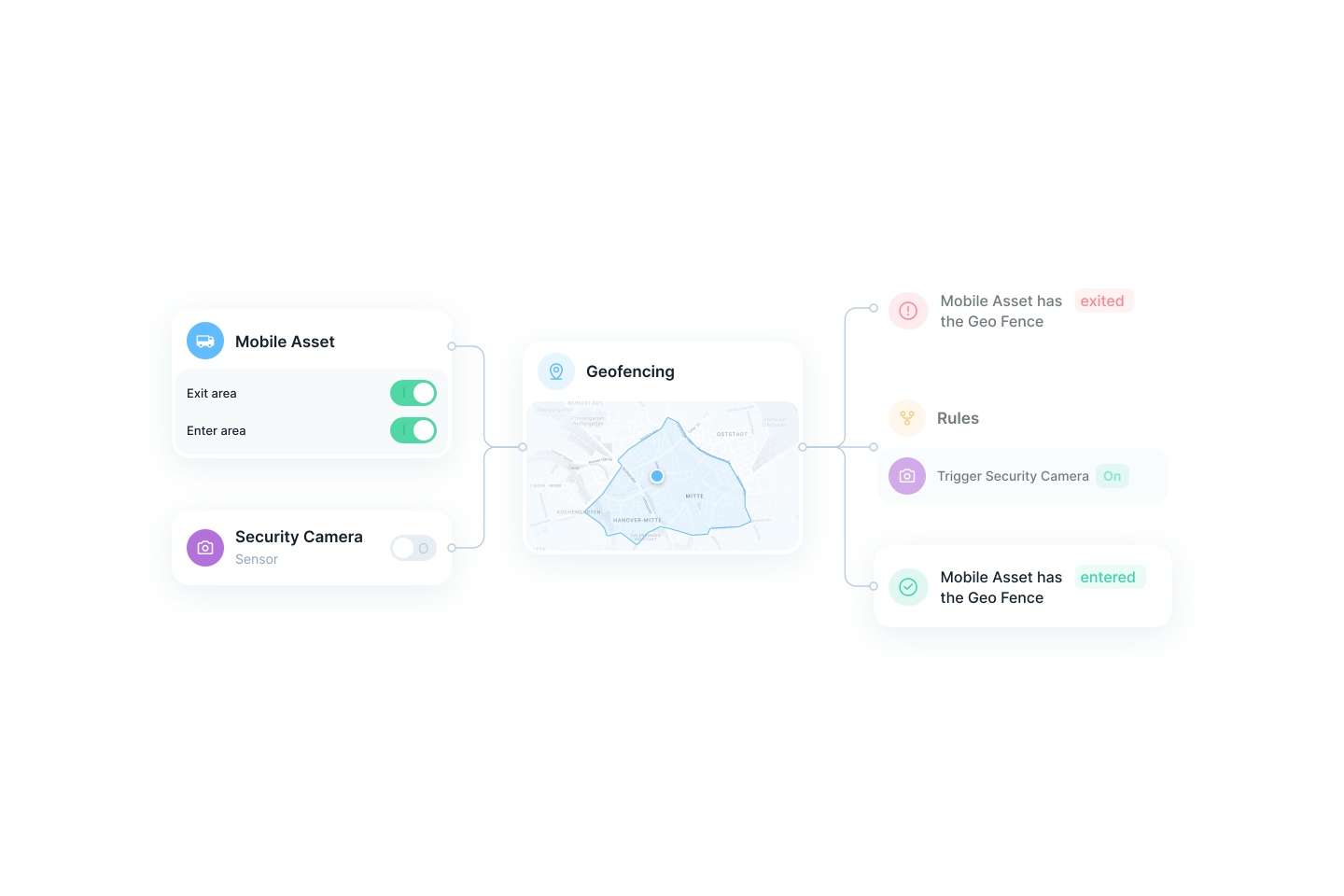

You can find details and features here:

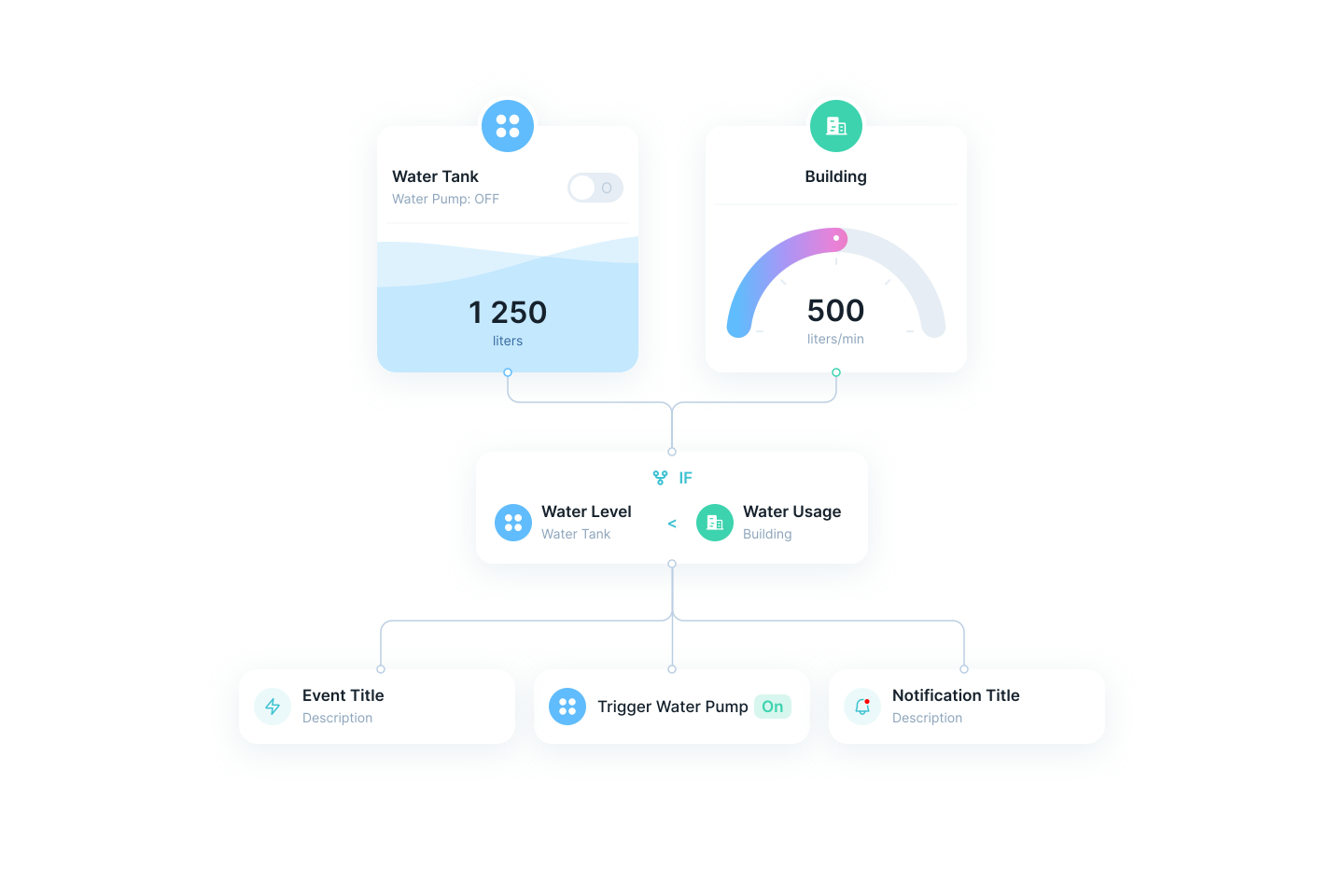

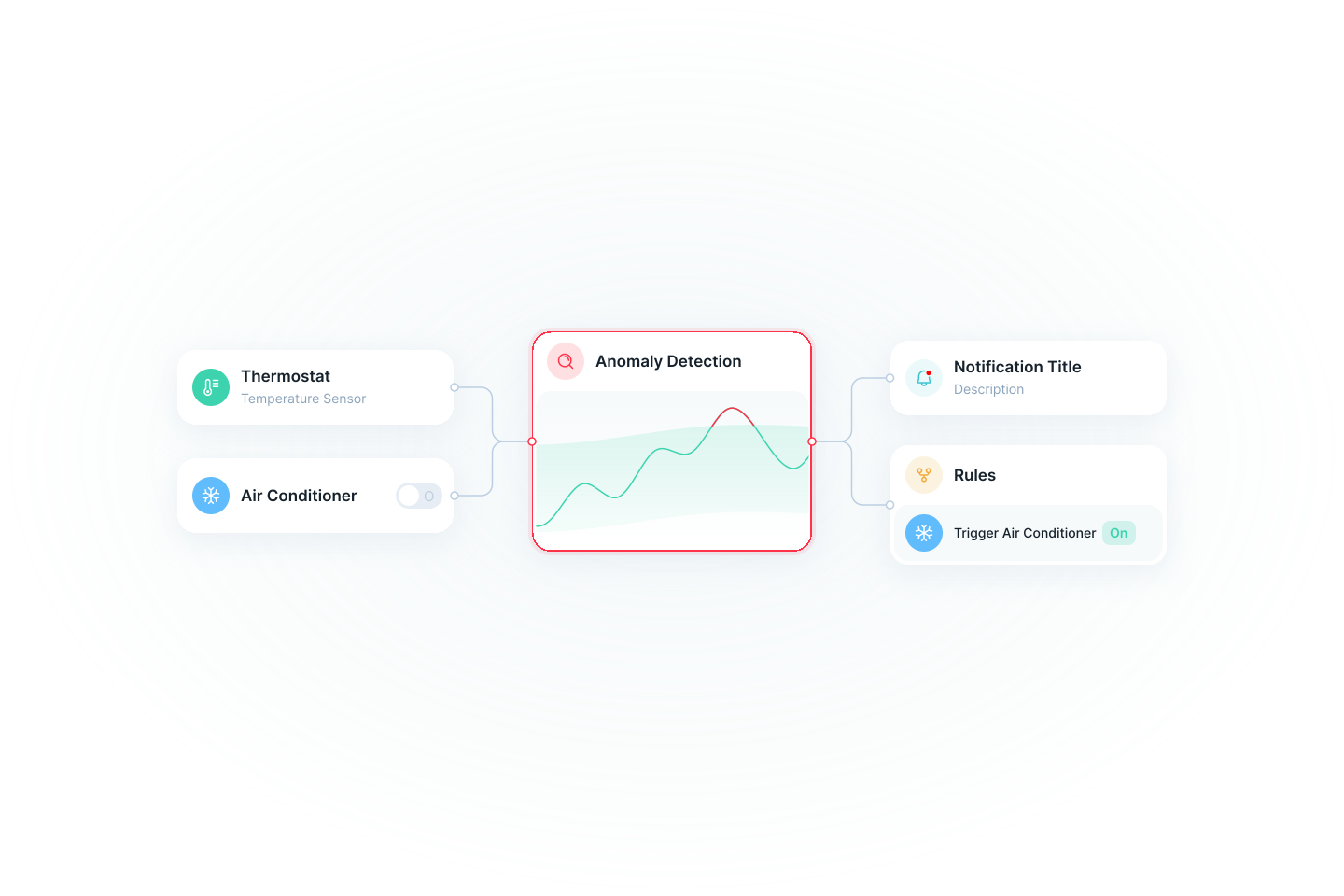

As a result, only the truly relevant rules are checked out of several thousand possible rules—this makes the difference between slow batch processing and super-fast real-time analysis.

Our engine performs well and is failure-proof, even with large IoT installations with thousands of sensors.

This makes the future of industrial data processing even smarter, faster, and more reliable.

Predictive Manufacturing

Anticipate spare parts production

Ensure early production of spare parts based on wear and usage data.

Take seasonal influences into account

Adapt production processes to seasonal fluctuations and weather conditions.

Consider supply chain aspects

Consistent planning and adaptation to current availability along the supply chain.